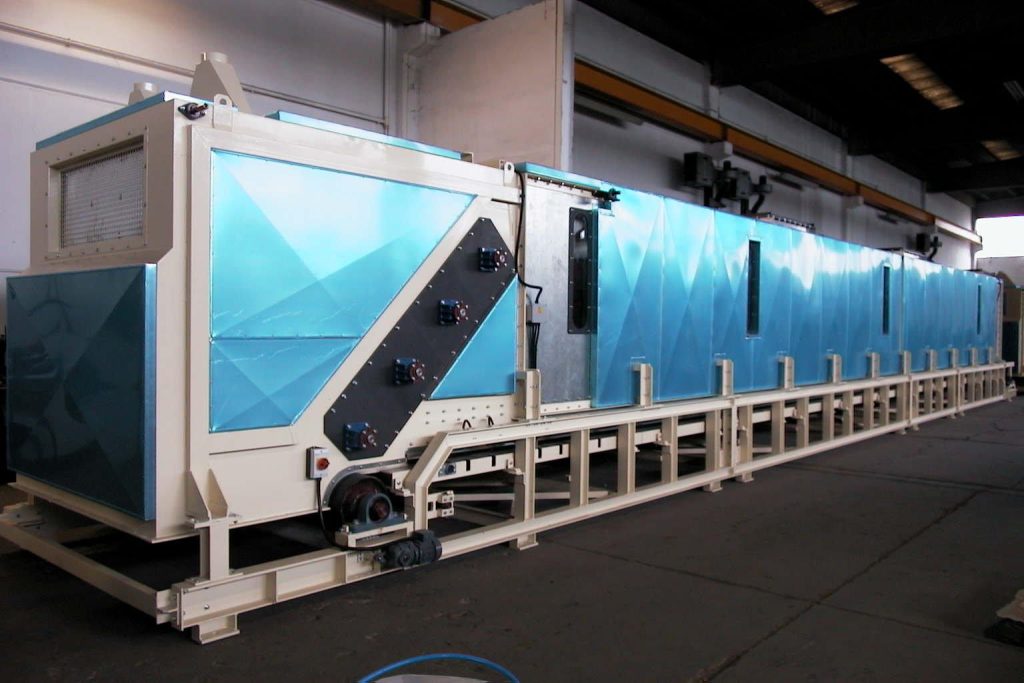

Unibelt bunkers are mainly used to dispense loose materials in the wood sector for biomasses and waste.

They consist of:

A storage chamber (up to 400 mc).

Via an upper scraping system, usually a chain conveyor or a set of screws, the available storage volume is filled up, which means the material moves to the fluidification head when the section is full.

The storage chamber can be fitted with explosion-proof doors, fire-prevention systems and doors to ensure rear unloading in the event of an emergency.

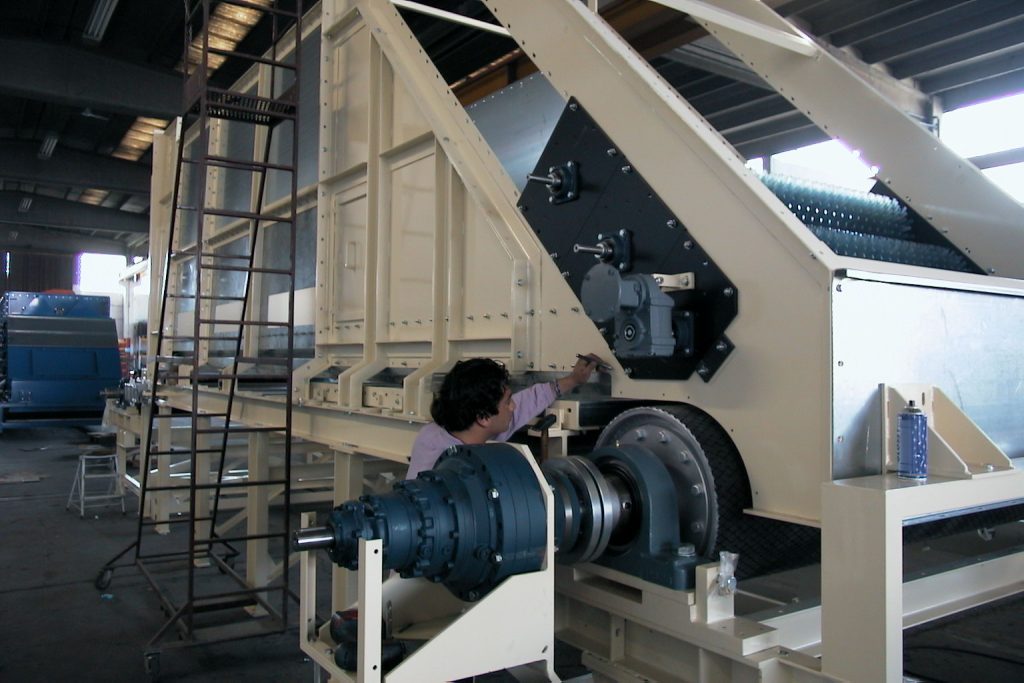

Fluidification head.It is designed to break up the section of material and consists of a series of motorised shafts that can be fitted with disks, hammers or diverging spirals according to the features of the material processed, humidity, specific weight (when the material is heaped together) and size.

Conveyor (up to 3000 mm wide).

The progress of the material is ensured by a conveyor, which may be either a belt conveyor or one with rubber-coated shutters. In both cases, the presence of double container flaps prevents the product from leaking out along the conveyor line, thereby ensuring a clean transport.

Accessories:

- Weighing system

- Cleaning brush

- Unloading extractor hood

- Double drive unit