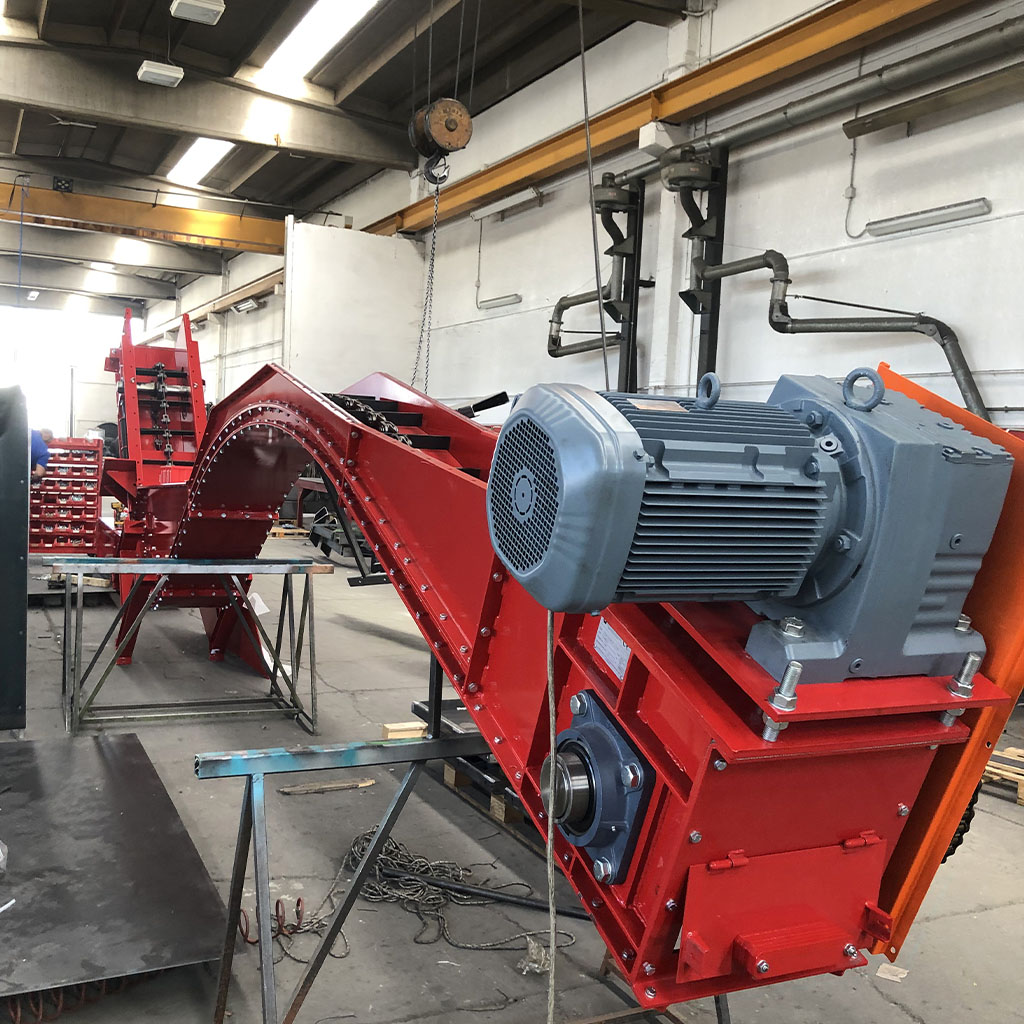

UNIBELT single-chain conveyors are made with a sturdy framing made of either metal, carbon steel or stainless steel. Used for simultaneous vertical/horizontal transport, they are particularly suitable for abrasive and dusty materials. The chains are pressed 18 NiCrMo 5 chains with shaped pins that are bent according to the kind of product conveyed. The manganese steel sliding guides ensure the durability of the casings.

The driving and stopper wheels have bolted crowns with a hardened C45 or Hardox 400 surface. This system guarantees quick disassembly and faster intervention. A single solution ensuring multiple unloading that can be controlled with pneumatic or mechanic shutters across the whole conveyor section. The design solutions and presence of special gaskets and seals prevent powder from leaking out, which ensures clean transport for the work environment.

- Single chain conveyor SCC: With single special designed drop-forged chain with scrapers and guides made in wear resistant steel bolted to the case. Suitable for the transport of bulk materials, including abrasive, capacity up to 150 tons per hours

- Single chain conveyor SCV: With single special designed drop-forged chain with scrapers and guides made in wear resistant steel bolted to the case. With double case is suitable for the transport of bulk materials, including abrasive, with slope up to 85 °.

- Single chain conveyor SSC: With single special designed drop-forged chain with scrapers and guides made in STAINLESS STEEL. Suitable for the transport of corrosive bulk materials, capacity up to 150 tons per hours.