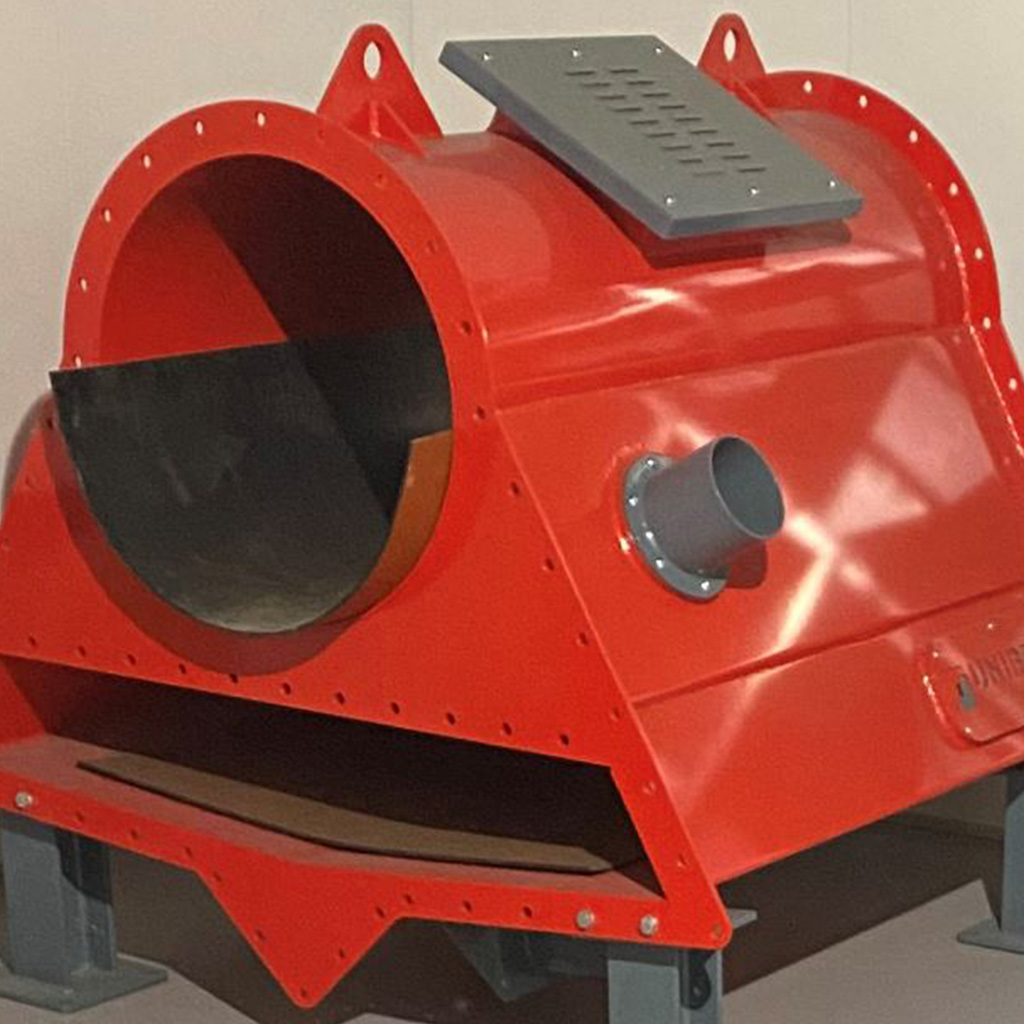

The Air Supported Conveyor Belt, our so called AirBelt and AirPipe are usually employed to handle bulk material at high speed without using the carry and return rollers.

This product has a distinctive feature: the belt slides on an air film that reduces the sliding friction between the belt and the frame. This eliminates resistance due to the rolling friction of the rollers in the conveyor section.

The AirPipe model is suitable for materials with sizes up to 200 mm, due to its self-supporting structural shape it can be held every 30 meters and with towers and ropes up to 80 meters.

- AirPipe PA: In the PA version the blowers are present also in the return section, it is used to transport semi-dry materials of medium dustiness, is totally enclosed, water and dust proof.

- AirPipe PS: The PS version is complete with a special flat bottom and Chevron type belt, it is used to transport dry and very dusty materials with inclinations up to 30 °. The PS type is totally enclosed dust and waterproof. The dust is conveyed under the return section and totally recovered in the carry side.

- AirPipe PR: The PR version is complete with return rollers with a guaranteed life of 50,000 hours, it is used to transport slightly dusty and wet materials. Without the blowers on the return side, the required power is lower than the PS and PA design.

The AirBelt model is used for the transport of materials with sizes up to 600 mm with capacity greater than 3000 cubic meters per hour and inclinations up to 30 °. It must be supported every 6 meters on a bridge or structure.

- AirBelt CR: The CR version is complete with return rollers with a guaranteed life of 50,000 hours, it is used to transport slightly dusty and wet materials. Without the blowers on the return side, the required power is lower than the CS and CA design.

- AirBelt CA: In the CA version the blowers are present also in the return section, it is used to transport semi-dry materials of medium dustiness, even the CA type is totally enclosed , water and dust proof.

- AirBelt CS: The CS version is complete with a special flat bottom and Chevron type belt, it is used to transport dry and very dusty materials with inclinations up to 30 °. The PS type is totally enclosed dust and waterproof. The dust is conveyed under the return section and totally recovered in the carry side.

- AirBelt SE: It is designed for the transport of powder and abrasive materials with adensity of 1.6 tons per cubic meter. It is suitable for the pre-mixe sector and for all sectors where it is necessary to maintain the aggregation state of the mixture.