History of UNIBELT

Unibelt srl has been operating in the transport and industrial automation sector since 1978 by making conveyor and systems for bulk materials and storage systems for packaged materials.

Unibelt operates in a variety of manufacturing sectors by designing and manufacturing top quality and reliable products, as well as providing guidance and full support to clients throughout all stages of production up to after-sales services. With the experience it acquired in various sectors, it can install specific solutions designed according to the kind of material they need to handle. The focus on applicable technological innovations enables the company to promptly meet clients’ needs.

Based in San Cesario sul Panaro near Modena, Unibelt brings together in a single structure departments with facilities for the design, production, assembly and commissioning of each individual product. The design department, consisting of design engineers who work on latest-generation CAD stations, acquired extensive experience by solving all the process issues associated with the production cycles they tackled.

Quality, durable and cost-effective products help achieve the company’s main objective: the client’s productivity.

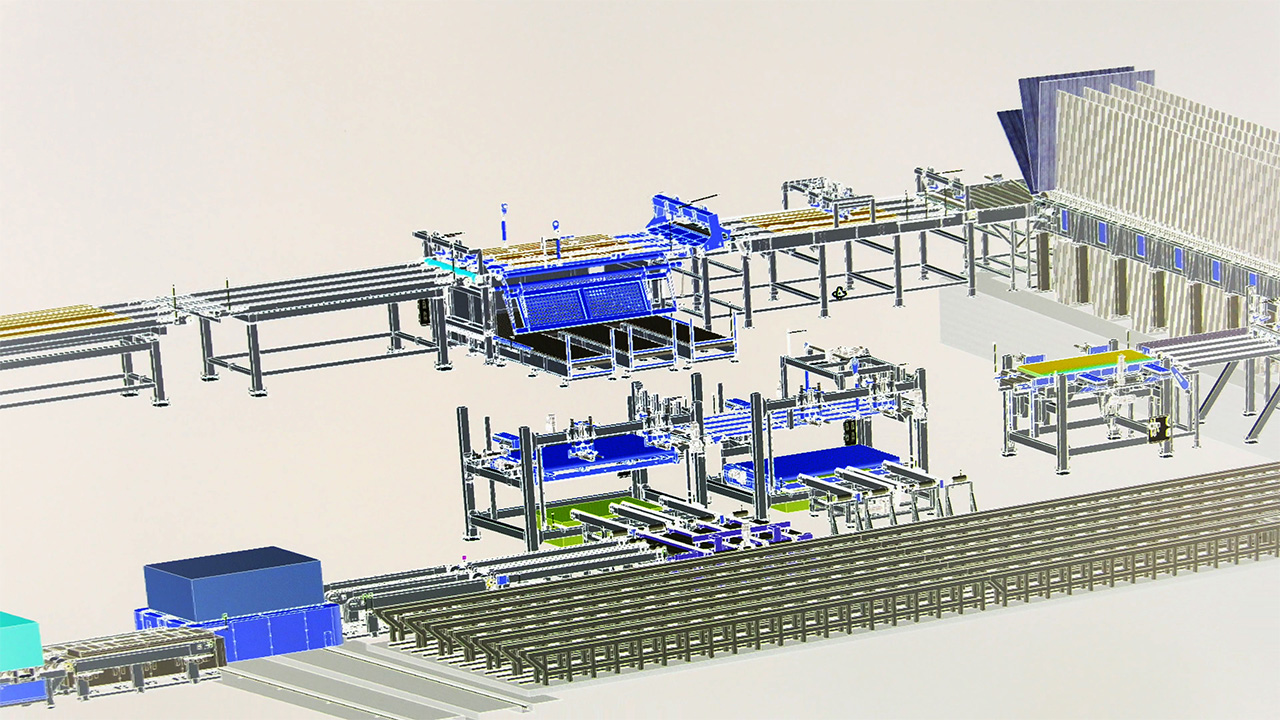

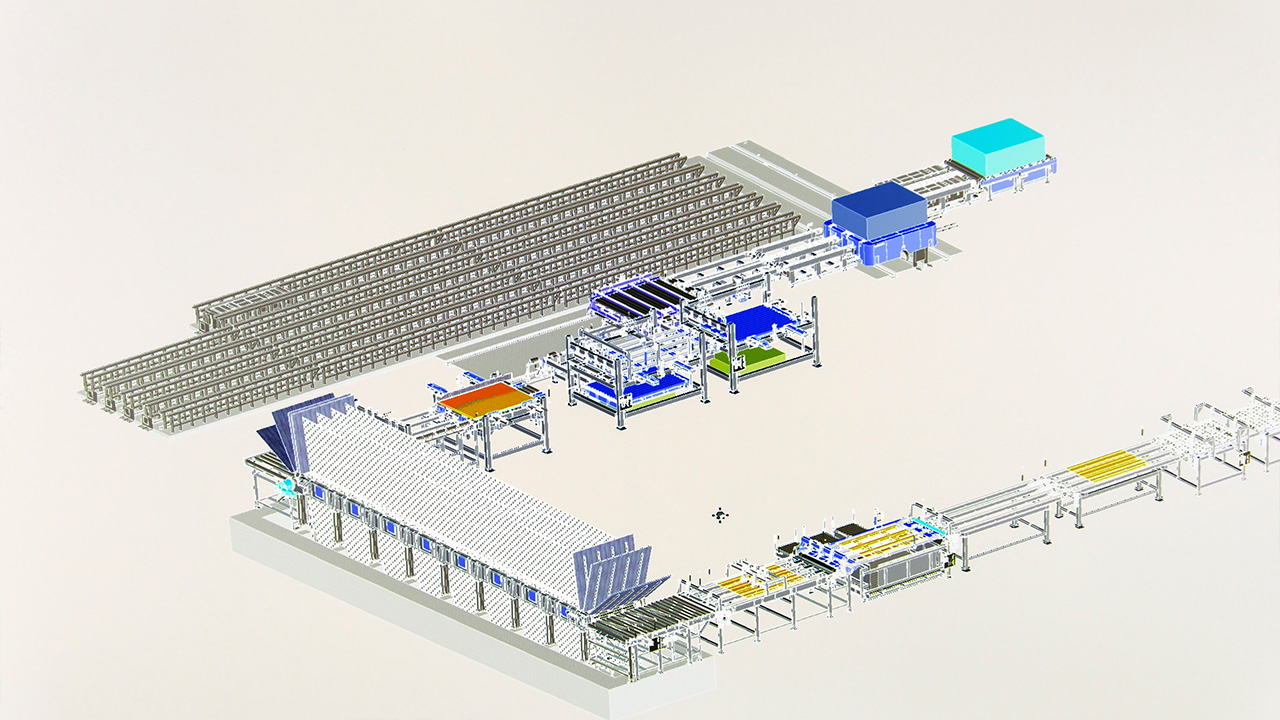

DESIGN

designs its machines in-house with the support of 3D and 2D software.

With new specific calculation and dynamic simulation software, we can ensure an immediate reply to clients and we can guide them in choosing the best kind of solutions.

PLANNING

After the design stage, the times to build the product and organise production are managed through the planning stage.

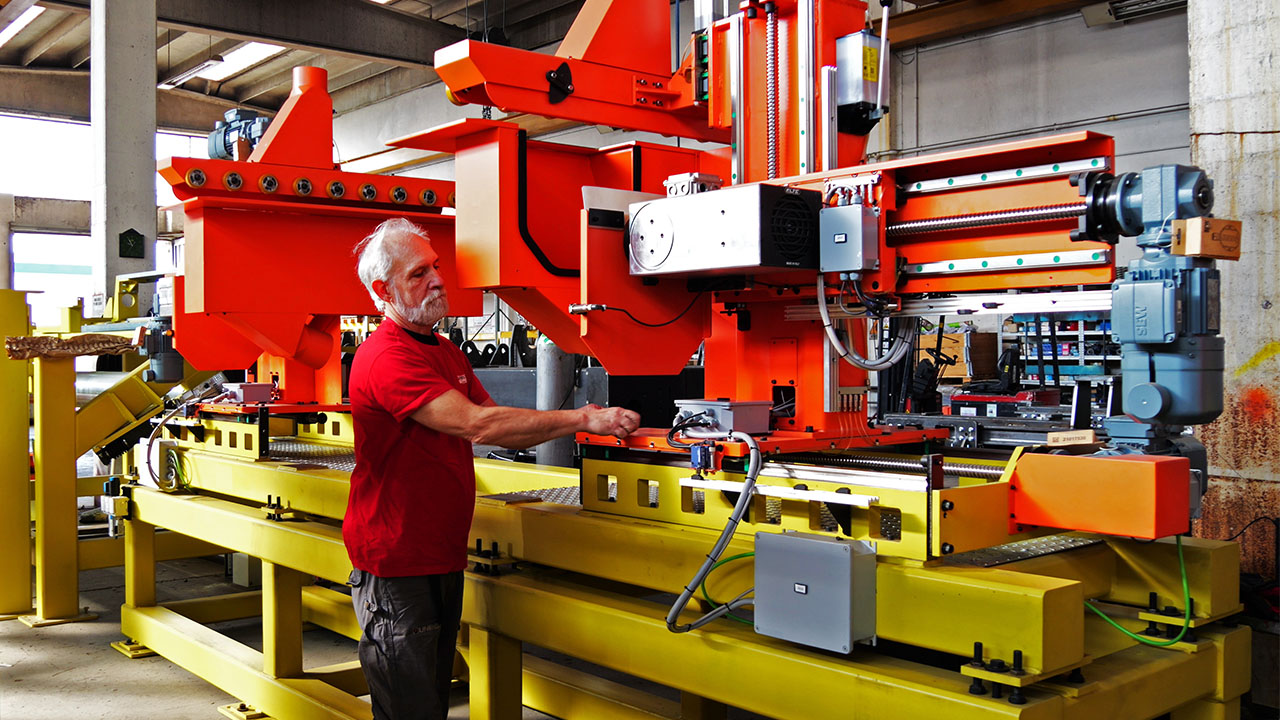

MANUFACTURING

Welding and specific processes, which can only be carried out by professionals, are performed with CNC machines and certified personnel, thereby ensuring solidity and longevity to our conveyors

PRE-ASSEMBLY

At all stages of production, we need to check everything matches the specifications in the drawing. This means that the framing of all the conveyors is pre-assembled before going ahead with the painting stage.

ASSEMBLY

After the painting stage, the conveyors are assembled by following the steps defined at the planning and design stage.

COMMISSIONING

Commissioning: the commissioning is carried out when the conveyor is operated under no-load conditions, with a special focus on: checking noise, vibrations and electrical consumption checking the mechanics, lubrication, surface treatments and tightening of bolts and nuts lifting tests

SHIPPING

After the commissioning stage, the conveyors are prepared for shipping, the packages are marked, the casings are setup and the packing lists are filled out.